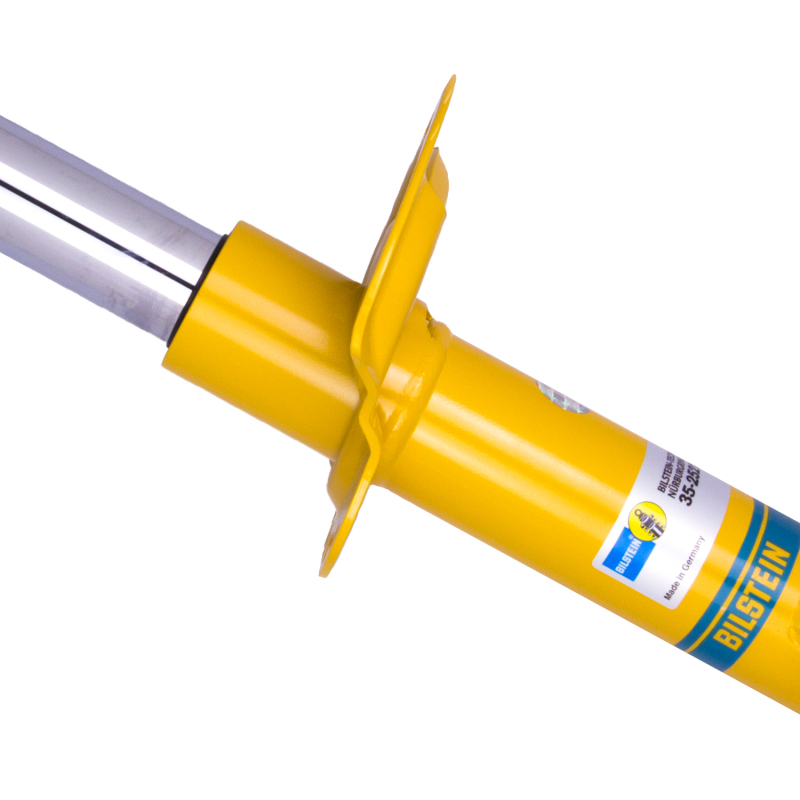

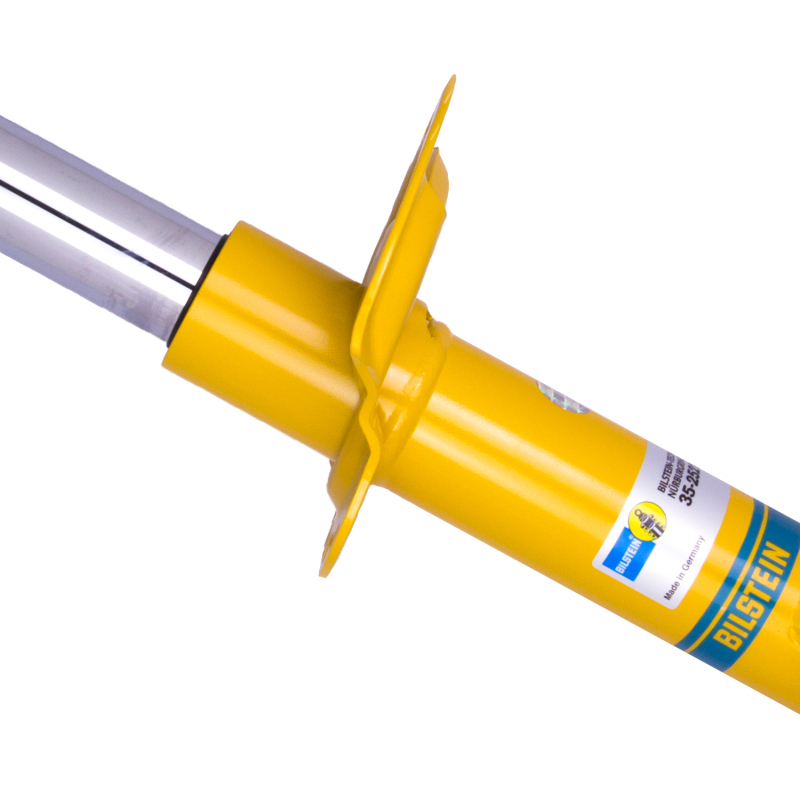

Ford Fusion Shocks - Front Left - Bilstein - Monotube Strut Assembly - `13-`20

Ford Fusion Shocks - Front Left - Bilstein - Monotube Strut Assembly - `13-`20

Available Options

Drive now, Pay later with Affirm

or with PayPal

Both options will be available upon checkout.

The Ford Fusion Shocks - Front Left - Bilstein - Monotube Strut Assembly - 2013-2020 is a high-performance suspension upgrade designed for Ford Fusion enthusiasts seeking enhanced driving dynamics and superior handling. Engineered by Bilstein, a leader in suspension technology, this monotube strut assembly is specifically crafted for those who demand optimal performance from their vehicle.

Detailing the attributes of this Bilstein B6 Performance Strut Assembly, it serves as a performance upgrade to the original factory suspension components. The monotube design ensures that any road imperfections are effectively absorbed for a smoother, more comfortable ride. Utilizing application-specific valve settings, this strut enhances the handling capabilities of your Ford Fusion, whether you're navigating city streets or twisty roads. The strut assembly is designed to pair seamlessly with the factory spring, offering a perfect balance between comfort and responsive handling. Rigorous testing assures that this strut assembly exceeds OE standards, providing reliable safety and unmatched performance.

Features

- Monotube design for improved shock absorption

- Engineered for Ford Fusion 2013-2020 models

- Application-specific valve settings

- Enhanced handling and safety

- Bilstein’s renowned gas-pressure technology

With these performance shock absorbers from Bilstein, you’ll experience the added benefit of optimal grip and increased lane stability, even in extreme situations. Should you have any questions or need further assistance, please feel free to call us directly. We're here to help at our two locations in Austin, Texas, and Los Angeles, California, where we also offer professional installation and customization services. Reach us at 512-982-9393 (TX) or 562-981-6800 (CA). If considering purchasing multiple items, contact us for possible shipping discounts. And remember, we provide on-premises professional installation at both locations to ensure your Ford Fusion performs at its best.

CA Residents: